Achieving Perfection in LED Assembly: Mastering the Art of Precision Engineering

Achieving perfection in LED assembly requires mastering the art of precision engineering. LED technology has become ubiquitous in our modern world, used in a wide range of applications, from lighting fixtures and automotive lighting to displays and electronic devices. To ensure the optimal performance and longevity of these applications, it is essential to meticulously assemble LEDs with the highest level of precision.

Precision engineering is all about the meticulous design and manufacturing of components with tight tolerances. When it comes to LED assembly, precision engineering plays a crucial role in aligning the various elements of an LED, such as the semiconductor chip, wire bonding, and encapsulation materials. Achieving precise alignment ensures the efficient transfer of light and minimizes the loss of lumens, resulting in brighter and more energy-efficient LEDs.

One crucial aspect of precision engineering in LED assembly is the accurate placement of the semiconductor chip. The chip is the heart of the LED, responsible for emitting light when an electric current is applied. Achieving precise alignment of the chip within the LED packaging is crucial to ensuring optimal light output. Any misalignment can result in reduced light intensity or uneven light distribution, negatively impacting the performance of the LED.

Wire bonding is another critical process in LED assembly that requires precision engineering. Wire bonding involves connecting the semiconductor chip to the electrical leads of the LED package. Achieving accurate wire bonding is crucial to ensure proper electrical connectivity and thermal dissipation. Any deviation in wire bonding can result in poor electrical conductivity or even electrical failure of the LED.

Encapsulation material is used to protect the semiconductor chip and wire bonding from environmental factors such as moisture and heat. Achieving precision in encapsulation involves carefully controlling the amount and distribution of the material. Insufficient encapsulation material can expose the chip and wire bonding to potential damage, while excess material can hinder the efficient transfer of light.

To achieve perfection in LED assembly, manufacturers employ advanced technologies and techniques. Automated assembly processes, such as pick-and-place machines and wire bonding machines, ensure consistent and precise placement of components. Robotic arms and vision systems are used to verify the alignment and quality of the assembled LEDs. Additionally, manufacturers employ stringent quality control measures, such as testing and inspection processes, to identify and rectify any deviations or defects.

Furthermore, continuous research and development in LED technology drive innovation in precision engineering. New materials and techniques are being developed to optimize the performance of LEDs. For example, quantum dots are being integrated into LED technology to enhance color accuracy and efficiency. Additionally, advancements in miniaturization and automation enable the manufacturing of smaller and more precise LED components.

In conclusion, achieving perfection in LED assembly requires mastering the art of precision engineering. Precise alignment of the semiconductor chip, accurate wire bonding, and optimal encapsulation are crucial for the optimal performance of LEDs. Manufacturers employ advanced technologies and rigorous quality control measures to achieve perfection in LED assembly. Continuous research and development in LED technology further drive innovation in precision engineering, improving the efficiency and performance of LEDs in various applications.

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

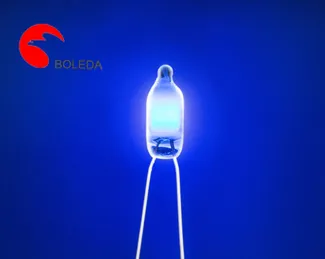

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)