Enhance Your Neon lamp Assembly Process for Spectacular Results

Enhancing the Neon lamp Assembly process can greatly improve the final results, resulting in spectacular neon signs and displays. By implementing the following steps and techniques, manufacturers can ensure precise assembly, consistent quality, and increased efficiency.

1. Preparing the Work Area:

Before starting the Neon lamp Assembly process, it is important to organize and prepare the work area properly. Clean and clear workstations help prevent any contamination that may affect the quality of the assembly. Additionally, ensure that all necessary tools and materials are readily accessible.

2. Safety First:

Working with neon lamps involves electrical components and potentially hazardous materials. It is crucial to prioritize safety throughout the assembly process. Provide proper personal protective equipment (PPE), such as gloves, goggles, and aprons, to protect workers from any potential injuries or exposure to harmful substances.

3. Quality Control:

Implementing a stringent quality control system is key to producing exceptional neon lamps. Perform regular checks to ensure that all components, including electrodes, glass tubing, and gas mixtures, meet the required specifications. Inspect each component for defects, such as cracks or impurities, as these can impact the performance of the final product.

4. Electrode Preparation:

The quality of the electrodes significantly affects the overall performance and longevity of the neon lamp. Proper electrode preparation involves cleaning, bending, and selecting the appropriate size and shape. Ensure that the electrodes are free from any dirt or oxidation before assembly to guarantee a stable electrical connection.

5. Glass Tubing Handling and Cleaning:

Handling and cleaning the glass tubing is a critical step in the Neon lamp Assembly process. Use lint-free gloves or tongs to avoid leaving fingerprints or oils on the glass surface. Clean the glass tubing thoroughly to remove any impurities that may interfere with the gas mixture inside. Ultrasonic cleaning or a chemical cleaning solution can be used to achieve optimal results.

6. Gas Filling and Sealing:

Accurate gas filling and precise sealing techniques are essential for achieving vibrant and long-lasting neon lamps. Use specialized equipment and instruments to fill the glass tubing with the appropriate gas mixture at the correct pressure. After filling, ensure a tight and leak-proof seal to prevent gas leakage or contamination. 7. Aging Process:

An aging process is crucial for neon lamps as it stabilizes and optimizes their performance. Implementing an aging procedure allows the electrodes and gas mixture to reach their optimal state, reducing the chances of flickering or dimming. The duration and conditions of the aging process may vary depending on the specific neon lamp type and manufacturer's recommendations.

8. Proper Mounting and Wiring:

Carefully mount and wire the neon lamps to ensure a secure and reliable installation. Use appropriate mounting brackets or supports that protect the glass tubing from physical damage and vibrations. Follow proper wiring techniques and ensure a consistent electrical connection between the electrodes and power supply. This will prevent any potential electrical issues that may affect the functioning of the neon lamp.

9. Finishing Touches:

After completing the assembly and installation, perform a final quality check on each neon lamp. Inspect for any defects, such as gas leakage, flickering, or uneven brightness. Make any necessary adjustments or repairs to achieve a perfect final product.

10. Efficient Packaging and Delivery:

Proper packaging is critical to protect the neon lamps during transportation. Use suitable packaging materials, such as foam or bubble wrap, to prevent any damage or breakages. Additionally, implement an efficient delivery system that ensures timely and safe delivery of the neon lamps to the customers.

By implementing these steps and techniques, manufacturers can enhance their Neon lamp Assembly process, resulting in spectacular and flawless neon signs and displays. This will not only meet the expectations of customers but also boost the reputation and competitiveness of the manufacturing company.

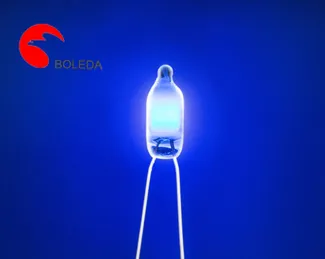

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)