Maximizing Productivity in LED Assembly: Proven Strategies for Optimal Efficiency

Maximizing productivity in LED assembly is crucial for companies to meet customer demands, maintain a competitive edge, and increase profitability. To achieve optimal efficiency, several proven strategies can be implemented.

1. Automating the assembly process: Automation can significantly improve productivity by reducing the need for manual labor and minimizing errors. Automated systems can handle repetitive tasks quickly and accurately, resulting in increased output. Robotic arms and pick-and-place machines are commonly used in LED assembly to improve efficiency and precision.

2. Streamlining the production flow: Analyzing the production flow and identifying bottlenecks or inefficiencies is essential to improve productivity. By optimizing the layout of the assembly line and implementing lean manufacturing principles, companies can eliminate unnecessary steps, reduce lead times, and increase overall efficiency.

3. Standardizing processes and procedures: Establishing standardized procedures ensures consistency in LED assembly, reduces errors, and enables easier training of new employees. By documenting best practices and providing clear instructions, companies can minimize variability and enhance productivity.

4. Implementing quality control measures: Quality control is crucial in LED assembly to ensure that all products meet the required specifications and performance standards. By conducting regular inspections and implementing rigorous testing protocols, companies can reduce the risk of defects and improve overall productivity by avoiding rework or customer returns.

5. Investing in employee training and development: Employees play a vital role in ensuring productivity in LED assembly. Providing comprehensive training programs and continuous professional development opportunities can enhance their skills and knowledge, enabling them to perform their tasks more efficiently. Well-trained employees are more likely to identify and resolve problems quickly, contributing to improved productivity.

6. Utilizing data analytics and real-time monitoring: Implementing data analytics tools and real-time monitoring systems can provide valuable insights into the production process. By collecting and analyzing data, companies can identify areas for improvement, track key performance indicators, and make data-driven decisions to optimize efficiency and productivity.

7. Investing in equipment and technology upgrades: Regularly upgrading equipment and adopting the latest technologies can significantly enhance productivity in LED assembly. Newer machines and tools often offer improved speed, accuracy, and reliability, leading to higher output and reduced downtime.

8. Implementing cross-training programs: Cross-training employees in multiple areas of LED assembly can help in allocating resources more efficiently. By having a workforce that is versatile and can perform different tasks, companies can adjust labor resources based on demand, prevent bottlenecks, and maximize productivity.

9. Implementing an effective supply chain management system: Optimizing the supply chain is essential to ensure a steady flow of materials and components needed for LED assembly. By establishing strong relationships with suppliers, implementing just-in-time inventory management, and reducing lead times, companies can minimize disruptions and maintain consistent production levels.

10. Continuously reviewing and improving processes: Regularly reviewing and evaluating Led Assembly processes is vital to identify areas for improvement and implement necessary changes. By encouraging employee feedback, conducting efficiency audits, and benchmarking against industry standards, companies can continuously improve productivity and stay ahead of the competition.

In conclusion, implementing these proven strategies can significantly enhance productivity in LED assembly. By automating processes, streamlining production flows, standardizing procedures, investing in employee training, utilizing data analytics, upgrading equipment, and continuously improving processes, companies can achieve optimal efficiency, meet customer demands, and increase profitability.

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

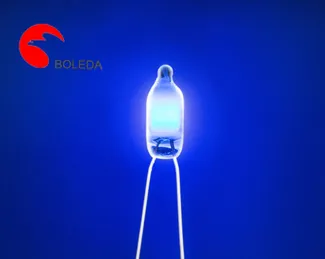

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)