Unveiling the Secrets Behind Flawless LED Assembly: Best-in-Class Techniques Revealed

LED (Light Emitting Diode) technology has revolutionized the way we light our homes, offices, and public spaces. With their energy efficiency, long lifespan, and versatility, LED lights have become the preferred choice for many lighting applications.

However, achieving flawless LED assembly is not a simple task. It requires a combination of best-in-class techniques and careful attention to detail. In this article, we will unveil some of the secrets behind flawless LED assembly and reveal the techniques used by industry leaders.

1. Automated Soldering Techniques: One of the key steps in LED assembly is soldering the LED chips onto the printed circuit boards (PCBs). To ensure consistent and reliable soldering, industry leaders use automated soldering machines. These machines utilize precise temperature control and robotic arms to ensure accurate placement and soldering of LED chips.

2. Thermal Management: LEDs generate heat, and effective thermal management is crucial for maintaining optimal performance and extending the lifespan of the LED modules. Industry leaders employ various techniques for heat dissipation, such as heat sinks, thermal pads, and advanced techniques like vapor chamber cooling. Proper thermal management not only prevents overheating but also improves the overall efficiency and reliability of the LED assembly.

3. Optical Optimization: LED lights are known for their excellent optical properties, such as high brightness and color accuracy. Achieving optimal optical performance requires careful alignment of the LED chips and lens arrangement. Industry leaders use advanced optical simulation software to optimize the design and placement of lenses, reflectors, and diffusers to ensure maximum light output and uniformity.

4. Quality Control and Testing: Flawless LED assembly goes beyond just the assembly process; rigorous quality control and testing are essential to ensure consistent performance and reliability. Industry leaders implement comprehensive quality control measures, such as visual inspection, automated testing equipment, and statistical process control techniques. These measures help identify any defects or inconsistencies early in the assembly process, ensuring that only high-quality LED modules reach the market.

5. Robust Interconnection: The interconnection between the LEDs, PCBs, and other components is critical for maintaining the integrity of the LED assembly. Industry leaders utilize advanced interconnect technologies, such as surface-mount technology (SMT) and flip-chip bonding, to ensure reliable electrical connections and mechanical stability. Robust interconnects help resist vibrations, temperature variations, and other environmental factors, making the LED assembly more durable and reliable.

6. Environmental Considerations: As sustainability becomes increasingly important, industry leaders are incorporating environmental considerations into their LED assembly techniques. This includes using lead-free soldering materials, eliminating toxic substances, and optimizing energy efficiency. By adopting eco-friendly practices, LED manufacturers not only reduce their environmental footprint but also meet the growing demand for sustainable lighting solutions.

In conclusion, achieving flawless LED assembly requires a combination of best-in-class techniques and attention to detail. Automated soldering techniques, thermal management, optical optimization, quality control and testing, robust interconnection, and environmental considerations are key factors that contribute to a successful LED assembly. By employing these techniques, industry leaders can deliver high-quality LED modules that meet the demands of today's lighting applications.

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

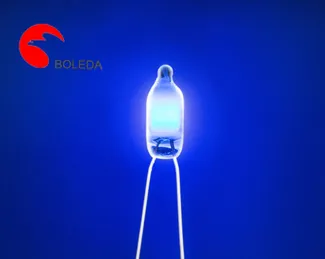

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)