What Makes a Successful Neon lamp Assembly? Find Out Now!

A successful Neon lamp Assembly relies on several key factors, including the selection of quality materials, precise manufacturing processes, and rigorous quality control measures. In this article, we will explore the various aspects that contribute to the success of a Neon lamp Assembly.

1. High-Quality Materials:

The use of superior materials is crucial in ensuring the longevity and efficiency of a Neon lamp Assembly. The choice of glass tube and electrode materials greatly affects the performance and durability of the lamp. High-quality glass tubes that have low impurity levels, excellent transparency, and can withstand high temperatures are essential. Similarly, the selection of high-grade electrodes, such as iron or copper, ensures a reliable electrical connection and reduces electrode erosion.

2. Precise Manufacturing Processes:

Accurate and precise manufacturing processes are essential for the success of a Neon lamp Assembly. The glass tube must be carefully shaped and sealed to protect the delicate neon gas and other gases inside. The bending and shaping of the tube require skilled craftsmen or advanced machinery to achieve the desired shapes. The process of bombarding the electrodes with high voltage to create the glowing effect must be controlled to ensure consistent colors and brightness across the entire Neon lamp Assembly.

3. Adequate Gas Filling:

The neon gas and other noble gases used in the lamp assembly play a crucial role in determining the color and intensity of the light emitted. The correct mixture and pressure of gases need to be precisely controlled to achieve the desired lighting effect. Proper gas filling techniques, such as using specialized gas filling apparatus and monitoring equipment, are essential to ensure the optimal gas mixture and pressure are achieved.

4. Efficient Power Supply:

A reliable and efficient power supply is essential for the successful operation of a Neon lamp Assembly. The power supply must be able to provide the required voltage and current to ensure the proper ionization of gases in the lamp. Additionally, the power supply should have built-in protection mechanisms to prevent overvoltage or overheating, which could damage the lamp or pose a safety hazard.

5. Comprehensive Quality Control:

To ensure the highest standards of quality, comprehensive quality control measures must be in place throughout the Neon lamp Assembly process. These measures include inspecting incoming raw materials, monitoring each stage of production, and conducting thorough testing of finished products. Visual inspections, electrical testing, and aging tests are commonly performed to identify any defects or issues that may affect the performance or safety of the Neon lamp Assembly.

6. Compliance with Safety Standards:

Compliance with safety standards and regulations is of utmost importance in the production of neon lamp assemblies. The manufacturing process should adhere to internationally recognized safety guidelines, such as those set by the International Electrotechnical Commission (IEC) or local regulatory bodies. Safety measures, such as proper insulation, grounding, and protection against electrical shocks, must be incorporated into the design and construction of the Neon lamp Assembly.

In conclusion, a successful neon lamp assembly requires the meticulous selection of high-quality materials, adherence to precise manufacturing processes, robust quality control measures, an efficient power supply, and compliance with safety standards. By focusing on these key aspects, manufacturers can produce neon lamp assemblies that are not only aesthetically pleasing but also reliable, durable, and safe to use.

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

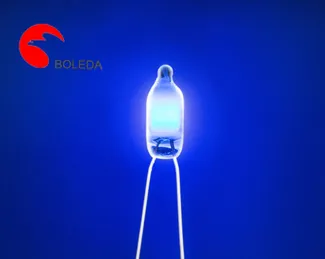

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)