Advanced Techniques for Streamlining LED Assembly: A Comprehensive Guide

Title: Advanced Techniques for Streamlining LED Assembly: A Comprehensive Guide

Introduction:

With the rapid advancements in LED technology, the demand for efficient and streamlined Led Assembly processes has increased. To keep up with the growing market, manufacturers are constantly seeking advanced techniques to optimize their assembly lines. This comprehensive guide aims to explore some of the most effective techniques for streamlining LED assembly, enabling manufacturers to improve productivity, reduce costs, and maintain the highest quality standards.

1. Automated Optical Inspection (AOI):

Implementing AOI systems in the Led Assembly process helps detect defects and inconsistencies in real-time. Utilizing high-resolution cameras and advanced algorithms, AOI can quickly identify issues such as solder defects, misplacement, or missing components. By eliminating manual inspection and minimizing human error, manufacturers can enhance production efficiency while ensuring product quality.

2. Robotic Assembly:

Integrating robotics into the assembly line can significantly reduce production time and increase accuracy. Robots equipped with advanced vision systems can handle delicate, small-sized LED components with precision and speed. Automated robots can efficiently perform tasks such as picking and placing components, soldering, and performing quality checks. The use of robots minimizes human intervention, lowers the risk of errors, and ensures consistent output.

3. Surface Mount Technology (SMT):

Switching to surface mount technology enables faster and more accurate placement of LED components. SMT eliminates the need for manual soldering by utilizing automated pick-and-place machines. These machines can place components accurately and at a high speed, resulting in improved productivity. Additionally, SMT reduces the size of LED circuit boards, leading to smaller and more compact LED products.

4. Design for Manufacturability (DFM):

Adopting DFM principles during the design phase of LED products can streamline the assembly process. Designers must consider factors such as component accessibility, ease of soldering, and optimized part placement. By optimizing the design for efficient assembly, manufacturers can minimize the chance of errors, reduce production time, and ultimately enhance the overall product quality.

5. Inline Testing:

Implementing inline testing procedures ensures the identification of defects early in the assembly process. Automated testing stations, placed strategically within the assembly line, can perform various tests such as electrical function testing, visual inspection, and thermal analysis. By detecting and addressing issues promptly, manufacturers can prevent the accumulation of defective units and minimize rework, resulting in improved productivity and quality.

6. Lean Manufacturing:

Adopting lean manufacturing principles can help eliminate waste and improve efficiency throughout the Led Assembly process. Techniques such as 5S organization, value stream mapping, and just-in-time production can reduce non-value-added activities, optimize workflow, and enhance overall productivity. By continuously identifying areas for improvement and implementing lean practices, manufacturers can achieve higher efficiency and lower production costs.

7. Training and Skill Development:

Investing in the training and skill development of assembly line workers is crucial for streamlining Led Assembly processes. Providing comprehensive training on operating machinery, understanding assembly techniques, and troubleshooting equipment can significantly reduce downtime due to errors or operational issues. Well-trained operators can contribute to improved productivity, higher quality standards, and consistent output.

Conclusion:

Streamlining Led Assembly processes is essential for manufacturers to stay competitive in the market and meet the increasing demand for LED products. By incorporating advanced techniques such as AOI, robotic assembly, SMT, DFM, inline testing, lean manufacturing, and skill development, manufacturers can achieve higher productivity, lower costs, and superior product quality. Continuous improvement and innovation in LED assembly techniques ensure manufacturers can maintain a competitive edge in this rapidly evolving industry.

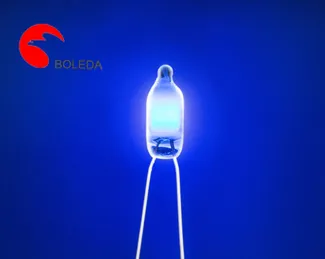

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)