Enhancing LED Assembly Efficiency: Cutting-Edge Strategies and Best Practices

Introduction:

The LED industry has witnessed significant growth in recent years due to the numerous advantages of LED technology over traditional lighting options. LED assembly plays a crucial role in determining the efficiency and performance of LED products. In this article, we will discuss cutting-edge strategies and best practices to enhance LED assembly efficiency.

1. Automated Assembly:

Implementing automated assembly processes is a key strategy to enhance LED assembly efficiency. Automated equipment such as pick-and-place machines, soldering robots, and automated optical inspection systems can significantly reduce production time and improve accuracy. These machines can handle high volumes of LED components with minimal human intervention, resulting in increased productivity and reduced labor costs.

2. Surface Mount Technology (SMT):

Surface mount technology is widely used in LED assembly for its cost-effectiveness and efficiency. SMT allows for the direct placement of LED components onto the PCB using automated equipment. This eliminates the need for manual assembly and reduces the risk of human errors. SMT also enables the miniaturization of LED products, making them more compact and lightweight.

3. Precision Placement:

Accurate placement of LED components is critical for achieving optimal performance. Utilizing advanced vision systems and automated placement machines with high precision capabilities ensures precise alignment of LEDs on the PCB. This not only enhances assembly efficiency but also improves the overall quality of LED products.

4. Thermal Management:

Efficient thermal management is essential for the longevity and performance of LED assemblies. Inadequate heat dissipation can lead to reduced luminous efficacy and premature failure of LEDs. Implementing effective thermal management techniques such as heat sinks, thermal pads, and proper thermal interface materials helps maintain optimal operating temperatures, ensuring the longevity and reliability of LED assemblies.

5. Quality Control:

Implementing strict quality control measures is crucial for enhancing LED assembly efficiency. Regular inspections and testing throughout the assembly process help identify and rectify any defects or issues at an early stage. Automated optical inspection systems can be used to detect faults in soldering, component placement, and connection integrity, ensuring a higher yield and reducing the need for rework.

6. Lean Manufacturing Practices:

Adopting lean manufacturing practices can optimize the Led Assembly process, resulting in increased efficiency and reduced waste. Identifying and eliminating non-value-added activities, implementing standardized work procedures, and optimizing material flow can streamline the assembly process, leading to improved productivity and reduced costs.

7. Continuous Improvement:

Continuously monitoring and analyzing the Led Assembly process is essential for identifying areas of improvement. Gathering feedback from operators and analyzing production data can help identify bottlenecks, cycle time inefficiencies, and opportunities for automation. Regularly reviewing and updating assembly procedures, equipment, and training programs ensures ongoing improvement in efficiency and performance.

Conclusion:

Enhancing LED assembly efficiency is crucial for the sustainable growth of the LED industry. By implementing cutting-edge strategies and best practices such as automated assembly, surface mount technology, precision placement, thermal management, quality control, lean manufacturing practices, and continuous improvement, manufacturers can optimize their assembly processes, increase productivity, and deliver high-quality LED products to meet the growing market demands.

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

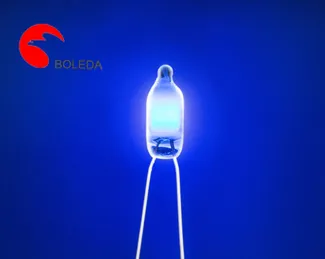

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)